Instrumentation and Measurement & Lab – Week #1 Lecture 1

Overview

1.1

Introduction

The technology

of controlling a series of events to transform a material into a desired end product

is called process control. For instance, the making of fire could be considered

a primitive form of process control. Industrial process control was originally

performed manually by operators. Their sensors were their sense of sight, feel,

and sound, making the process totally operator-dependent. To maintain a process

within broadly set limits, the operator would adjust a simple control device.

Instrumentation and control slowly evolved over the years, as industry found a

need for better, more accurate, and more consistent measurements for tighter

process control. The first real push to develop new instruments and control

systems came with the Industrial Revolution, and World Wars I and II added

further to the impetus of process control. Feedback control first appeared in

1774 with the development of the fly-ball governor for steam engine control,

and the concept of proportional, derivative, and integral control during World

War I. World War II saw the start of the revolution in the electronics industry,

which has just about revolutionized everything else. Industrial process control

is now highly refined with computerized controls, automation, and accurate

semiconductor sensors.

1.2 Control

Systems

Let’s start by

discussing an example of a control system that is encountered in everyday life.

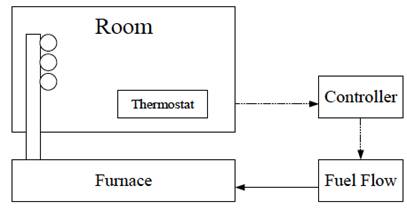

Consider a simple heating system shown in Figure 1. The house, in a cold

climate, can be maintained near a desired temperature by circulating hot water

through a heat exchanger. The temperature in the room is determined by a

thermostat, which compares the measured value of the room temperature to a

desired range, say 64-72 oF. If the temperature below

64, the furnace and pump are turned on, and if the temperature is above 72, the

furnace and pump are turned off. If the temperature is between 64-72 oF, the furnace and pump status remains

unchanged. This approach is termed “ON/OFF” control and can be used when

precise control at the desired value is not required. Based on this example we

identify the following common control features:

- Control system uses a specific value or

range as the desired value for the controlled variable. The term set point

is usually used for the desired value.

- The conditions of the system are

measured; that’s all control systems use sensors to measure the physical

variables that are to be maintained near their desired values.

- Each control system has a control

calculation “algorithm”, which uses the measured and desired values to

determine a correction to the process operations. The control calculation

for the room heater is very simple (on/off) where the calculations used in

other systems may be very complex.

- The results of the control calculation

are implemented by adjusting some item of equipment in the system, which

is termed the final control element such as the furnace and pump switches.

Figure 1: Feedback control for room temperature

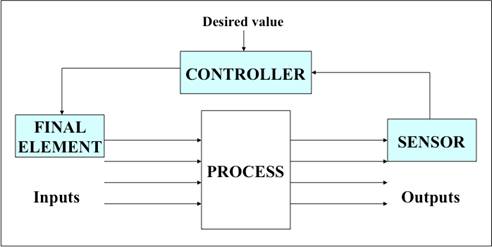

These major

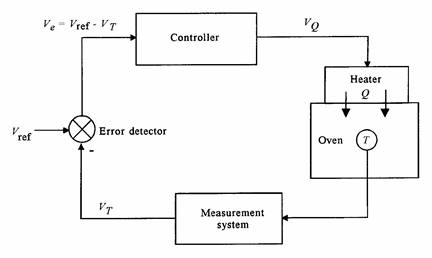

components are shown schematically in Figure (2), which can be used to

represent many control systems.

Figure 2: Schematic diagram of general feedback

control system

The given

control example have an additional feature that is extremely important. This is

feedback, which is defined as follows: feedback control makes use of an output

of a system to influence an input to the same system. In our example, the

temperature of the room is used, through the thermostat on/off decision to

influence the hot water flow to the exchanger. The importance of feedback can

be seen by considering the alternative without feedback. For example, an

alternative approach for achieving the desired room temperature would set the

hot water flow based on the measured outside temperature and a model for heat

loss of the house. This type of predictive approach is termed feed-forward

control. The strategy without feedback would not maintain the room near the

desired value if the model had errors-as it always would. Some causes of model

error might be changes in external wind velocity and direction or inflows of

air through open windows. On the other hand feedback control can continually

manipulate the final control element to achieve the desired value. Thus,

feedback provides powerful feature of enabling a control system to maintain its

desired value without requiring an exact plant model.

When used in

discussing control systems the terms input and output do not necessarily refer

to material moving into and out of the system. Here, the term input refers to a

variable that causes an output. In the room heating example, the input is the

fuel to the furnace, and the output is the room temperature. The casual

relationship inherent in the physical process forces us to select the input as

the manipulated variable and the output as the measured variable.

1.2.1.

Process – Control Principles

A key factor

in engineering is the design of the process so that it can be controlled well.

A more responsive plant would be easier to control. By responsive we mean that

the controlled variable responds quickly to adjustments in the manipulated

variable. Also, a plant that is susceptible to few disturbances would be easier

to control. Reducing the frequency and magnitude of disturbances could be

achieved by many means; a simple example is placing a large mixing tank before

a unit so that feed composition upsets are attenuated by the averaging effects

of the tank.

1.2.2

Servomechanisms

Another

commonly used type of control system, which has a slightly different objective

from process control, is called a servomechanism. A servomechanism,

sometimes shortened to servo, is an automatic device that uses

error-sensing negative feedback to correct the performance of a mechanism.

The term correctly applies only to systems where the feedback or

error-correction signals help control mechanical position, speed or other

parameters. For example, an automotive power window control is not a

servomechanism, as there is no automatic feedback that controls position—the

operator does this by observation. By contrast a car's cruise control uses

closed loop feedback, which classifies it as a servomechanism.

Figure 3: Servomotor

1.2.3

Discrete-State Control Systems

Discrete-state

control systems control a sequence of events, rather than regulation or

variation of individual variables. The starting and stopping of events is a

discrete-based system. The event is either true of false. This type of control

system can also be made automatic and is perfectly suited for computer-based

controllers.

1.3

Process-Control Block Diagram

As in other systems,

a block diagram may be used to model the process control system.

1.3.1

Identification of Elements

Process - The system which is

controlled is called the process, or sometimes the plant. The

output of the process is the variable or variables, such as the temperature,

level, flow, pH or pressure, which are desired to be controlled or regulated.

For example, to control temperature, heat must be added or removed from a

volume of chemical. The process may consist of the flow of steam or the flow of

cooling liquid or both. How the chemical responds to more steam flow or more

cooling liquid is the process.

Measurement

- The

conversion of the variable into some corresponding analog or digitally encoded

signal is a measurement. A sensor or transducer is a device that

performs this task. Further transformation may be required or signal

conditioning may be needed.

Error

Detector -

An error detector is required to determine if the measurement from the sensor

is above or below the desired setpoint, or if there is no error. In either case

the error is the signal that indicates that control action is required.

Controller

- The

controller examines the input from the error detector and determines what

action to take. The controller requires an input of both the measured

indication of the controlled variable and a representation of the setpoint.

Control

Element -

The final element in the process-control operation is the device that exerts a

direct influence on the process. The control element may also be referred to as

the final control element. Sometimes a device like a motor may be required to

control the speed of a conveyor or the position of a valve. This device is

referred to as an actuator.

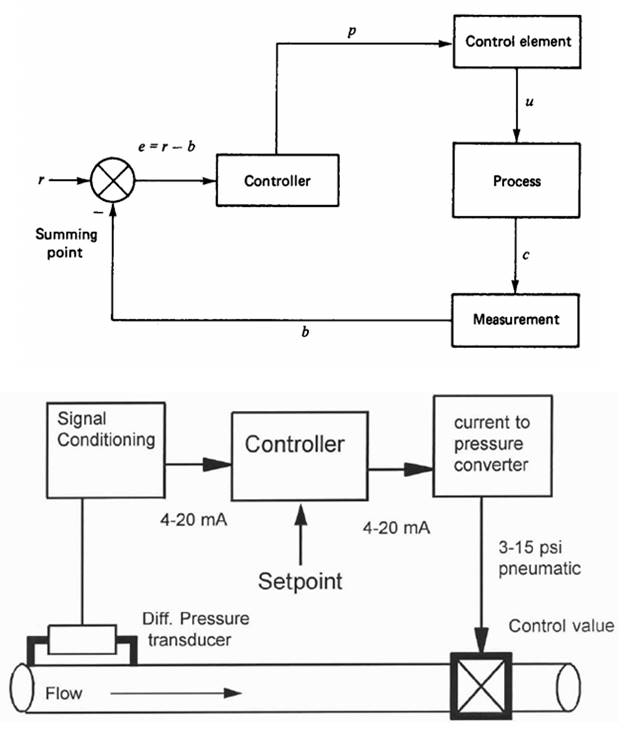

1.3.2 Block

Diagram

The block

diagram provides a simpler overview of the system to be analyzed.

Figure 5: A practical system

The Loop - The process control

block diagram describes the flow of signals from the measured variable to the

error detector, the controller and to the final control element. In general,

this configuration is referred to as a control loop or feedback loop because we

determine an error and feed back a correction to the

process.

1.4 Control

System Evaluation

The variable

used to measure the performance of the control system is the error e(t),

which is the difference between the constant set point, or reference value, r,

and the controlled variable, c(t).

e(t) = r-c(t).

Since the

value of the controlled variable may vary with time, so may be error.

Control

System Objective -

The objective of a control system is best represented by three requirements:

- The system should be stable.

- The system should provide the best

possible steady state regulation.

- The system should provide the best

possible transient regulation.

1.4.1

Stability

The purpose of

the control system is to regulate the value of some variable. This requires

that action be taken on the process itself, in response to a measurement of the

variable. If this is done correctly, the control system can cause the process

to become unstable. The tighter we try to control the variable, the greater the

possibility of system instability. Typically, as the control system is adjusted

to give better control, the likelihood of instability also increases.

1.4.2

Steady State Regulation

The steady

state error is the error after the transient response has decayed, leaving only

the continuous response. In other words, it is the error after everything has settled

out. For instance, it might be the error remaining after oscillations in

the response have ceased. The objective of the best possible steady state

regulation simply means that the steady state error should be a minimum. When a

control system is specified, there will be some allowable deviation about the

set point. This means that variations of the variable within this band are

expected and acceptable.

1.4.3

Transient Regulation

Transient

regulation specifies how the control system reacts to bring the controlled

variable to the new set point. Another type of transient influence is a sudden

change of some other process variable. The controlled variable depends on other

process variables. If one of them suddenly changes value, the controlled

variable may be driven to change also, so the control system acts to minimize

the effect. This is called transient response.

1.4.4

Evaluation Criteria

The question

of how well the control system is working is thus by (1) ensuring stability, (2)

evaluating steady state response, and (3) evaluating the response to set point

changes and transient effects. The term tuning is used to indicate how a

process control loop is adjusted to provide the best control.

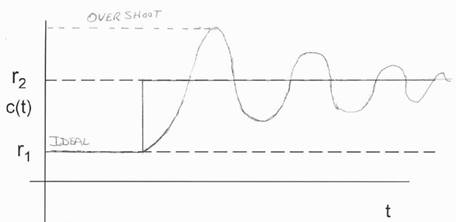

Damped

Response -

If a system responds to a set point change or a transient disturbance with an

error of only one polarity (no oscillations), the system displays a damped

response. Different tuning will provide different values of maximum error.

Cyclic

Response -

If a system responds to either a set point change or a transient disturbance

with an oscillation of the error about the set point, the system displays a

cyclic response. Parameters of interest are the maximum error and the duration

of the oscillations, also called the settling time. The duration is measured

from the time when the allowable error is first exceeded, to the time when it

falls within the allowable error and stays. This response is modified by

adjusting the control loop parameters, which is called tuning. A number of

standard cyclic tuning criteria are used. Two common types are minimum area and

quarter amplitude. In minimum area, the tuning is adjusted until the net area

under the error time curve is minimum. The quarter amplitude criterion

specifies that each peak of the cyclic response shall be a quarter of the

amplitude of the preceding peak.

1.5 Analog

and Digital Processing

Variables are

analog in nature, and before digital processing evolved, sensor signals were

processed using analog circuits and techniques, which still exist in many

processing facilities. Most modern systems now use digital techniques for

signal processing.

1.5.1 Data

Representation

Analog Data: Signal amplitudes are

represented by voltage or current amplitudes in analog systems. Analog

processing means that the data, such as signal linearization, from the sensor

is conditioned, and corrections that are made for temperature variations are

all performed using analog circuits. Analog processing also controls the

actuators and feedback loops. The most common current transmission range is 4

to 20 mA, where 0 mA is a fault indication.

Digital

Data:

Signal amplitudes are represented by binary numbers in digital systems. Since

variables are analog in nature, and the output from the sensor needs to be in a

digital format, an analog to digital converter (ADC) must be used, or the

sensor’s output must be directly converted into a digital signal using

switching techniques. Once digitized, the signal will be processed using

digital techniques, which have many advantages over analog techniques, and few,

if any, disadvantages. Some of the advantages of digital signals are: data

storage, transmission of signals without loss of integrity, reduced power

requirements, storage of set points, control of multiple variables, and the

flexibility and ease of program changes. The output of a digital system may

have to be converted back into an analog format for actuator control, using

either a digital to analog converter (DAC) or width modulation techniques.

1.5.2

On/off Control

Room

temperature control utilizing a thermostat is an example of on/off control.

When the temperature drops below the set point, the thermostat turns the heater

on. When the temperature reaches the set point, the thermostat turns the heater

off. A dead band could be utilized in the thermostat to establish a

temperature range where no action will occur. Hysteresis means that the

behavior of the system is different at the same value of temperature, depending

on whether the temperature is increasing or decreasing.

1.5.3

Analog Control

True analog

control exists when all variables in the system are analog representations of

another variable.

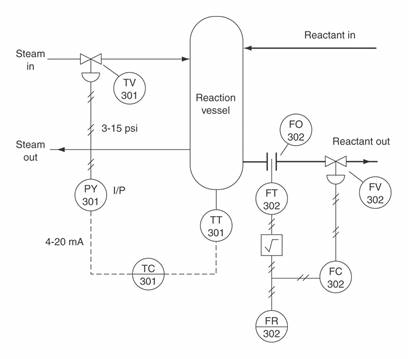

Figure 7: Analog control system such as this

allows continuous variation of some parameter, such as heat input, as a function

of error.

1.5.4

Digital Control

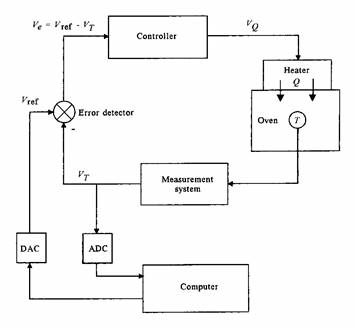

Digital

control involves the use of a computer in modern applications; although in the

past, digital logic circuits were also used.

Supervisory

Control -

Supervisory control means a remotely mounted controller could be monitored from

a central location, such as a control room. However, control still is executed

at the controller.

Direct

Digital Control -

As computers have become more reliable and miniaturized, they have taken over

the controller function.

Smart

Sensor -

With microprocessor large-scale integration, the controller can be embedded in

the sensor itself. The most current technology today is to interface smart

sensors in a local area network or field bus.

Networked

Control Systems -

In order to have coordinated control throughout a large plant site, digital

control units may be placed on a local-area network utilizing a variety of

carriers such as fiber optic cables, as well as metallic conductors. The most

commonly implemented standards are the Foundation Fieldbus and the Profibus.

Figure 8: In Supervisory control, the computer

monitors measurements and updates setpoints, but loops are still analog in

nature.

1.5.5

Programmable Logic Controllers

Manufacturing

operations may be on/off in nature. In the past, much of this control utilized

relays. Computers have also taken over the operation of such relay logic

controllers. Special microprocessor based computers designed for discrete

control are called programmable logic controllers or PLC’s.

Figure 9: A Programmable Logic Controller

1.6 Units,

Standards, and Definitions

Common units,

standards and definitions are utilized in process control.

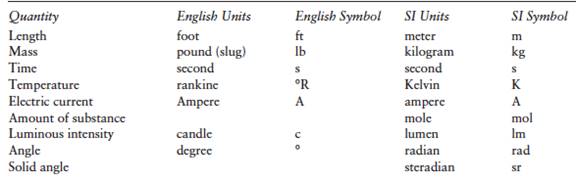

1.6.1 Units

A particular set

of metric units is used, called the international system or SI. It is also

important for the process control specialist to know English units and be able

to perform conversions between the SI system.

International

System of Units -

The international system is based on seven well-defined base units in two

supplementary, dimensionless units. Please refer to the table on page 22 in the

text.

Standard

metric prefixes are also applied to the standard units – refer to appendix 1.

1.6.2

Analog Data Representation

For

measurement systems or control systems, part of the specification is the range

of the variables involved. Two analog standards are in common use as a means of

representing the range of variables in control systems. For electrical systems,

we use a range of electric current carried in wires; and for pneumatic

systems (systems where air pressure and flow are used to measure, control and

interact with the process), we use a range of gas pressure carried in pipes.

Current

Signal -

The most common current transmission signal is 4 to 20ma.

Pneumatic

Signals -

In the United States, the most common standard for pneumatic signal

transmission is 3 to 15 psi.

1.6.3

Definitions

Following are

some common terms and expressions used to describe process control elements.

Error - When used for a

controlled variable and a control system, error is the difference between the measured

value of the variable and the desired value: that is, the reference or set

point value.

Block

Definitions -

Control systems are often described in terms of blocks. One block represents

the measurement, one the controller, and so on.

Transfer

Function -

The transfer function describes the relationship between the input and output

for the block. It is usually a mathematical expression that describes the

relationship.

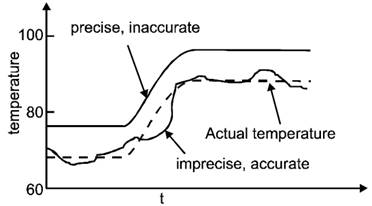

Accuracy - Accuracy is used to

specify the maximum overall error to be expected from a device. Accuracy is

usually expressed as the inaccuracy and can appear in several forms.

- Measured variable

- Percentage of the instrument full-scale

reading

- Percentage of instrument span

- Percentage of the actual reading

System

Accuracy -

Often, one must consider the overall accuracy of many elements in a process

control loop to represent a process variable. The best way to do this is to

express the accuracy of each element in terms of the transfer functions.

Sensitivity

-

Sensitivity is a measure of the change in output of an instrument for a change

in input.

Hysteresis

and Reproducibility -

An instrument may not have the same output value for a given input in repeated

trials. Such variation can be due to inherent uncertainties that imply a limit

on the reproducibility of the device. Hysteresis is when a different reading

results depending on whether the input value is approached from higher or lower

values.

Resolution

-

Measurement devices have a minimum measurable value of their input variable,

which is called the resolution.

Linearity - A linear relationship

between two variables results in a straight-line. A linear relationship between

input and output is highly desirable.

1.6.4

Process Control Drawings

Process control

drawings employ a standard set of symbols and definitions to represent a plant

and its associated control systems. This standard was developed by the American

National Standards Institute and the Instrumentation Systems and Automation

Society (ISA). Detailed process control diagrams are shown on what are called

piping and instrumentation diagrams or P&ID drawings.

Essential

Elements -

The P&ID depicts the entire plant and associated control systems. This

includes plant operating units, product flow lines, measurement and control

signal lines, sensors, controllers, final control elements, computers and

programmable logic controllers.

Instrument

Lines Symbols -

The standard current signal is represented as a dashed line. A pneumatic signal

is represented as a line with crosshatches. A digital data line to or from a

computer is represented as a solid line with small bubbles.

Other

Symbols -

Refer to appendix 5 for the symbols defined by the standard.

1.7 Sensor

Time Response

A sensor also

has a time constant that specifies how the output changes in time when the

input is changing in time. This dynamic transfer function, which is independent

from the static transfer function, is often simply called the time response. It

is particularly important for sensors because they are the primary element for

providing knowledge of the controlled variable value.

1.7.1

First-Order Response

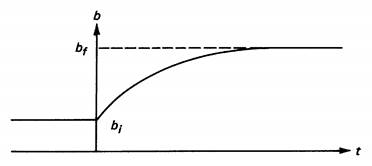

The simplest

time response is the first order response. The time response is determined by

the solution of a first-order differential equation.

Time

Constant -

The time constant r is part of the specification of the sensor. The time

constant is sometimes referred to as the 63% time, the response time, or the

e-folding time.

Real-Time

Effects -

The concept of an exponential time response and associated time constant is

based on a sudden change of the input value. In the real world, such

instantaneous changes occur rarely, if ever, and thus a worst-case situation in

the time response.

Figure 12: First-order response

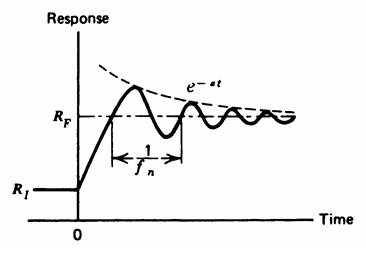

1.7.2

Second-Order Response

Some sensors

oscillate for a time before settling down to a value that corresponds to the

new input. Such oscillation and decay is a function of the sensor. This is

called a second-order response. Such a transducer will track the input when the

input changes in a time that is greater than the period represented by the

natural frequency. The damping constant defines the time one must wait for a

disturbance at t=0 for the transducer output to be a true indication of a

transducer input.

Figure 13: Second-order response

1.8

Significance and Statistics

1.8.1

Significance in Measurement

The number of

significant figures is indicated either by readability, in the case of analog

instruments, or by the number of digits, in a digital instrument.

Significance

in Calculations -

In calculations, the answer can have no more significance than the least of the

numbers used in the calculation.

Significance

in Design -

Whenever measurement is suggested, the figures given are assumed to be the

significant figures.

1.8.2

Statistics

Confidence in

the value of a variable can be improved by elementary statistical analysis of

measurements.

Arithmetic

Mean -

If many measurements of a particular variable are taken, the arithmetic mean

may be calculated to obtain an average value for the variable.

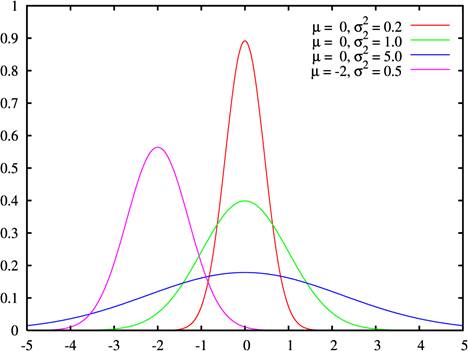

Standard

Deviation -

Often, it is insufficient to know the value of the arithmetic mean of a set of

measurements. To interpret the measurements properly, it may be necessary to

know something about how individual values are spread out about the mean. The

standard deviation of a group of variables will give an indication of this

distribution.

Interpretation

of Standard Deviation - Under certain assumptions, the standard deviation and data

are related to a special curve called the normal probability or bell curve. If

this is true, then 68% of all readings lie within one standard deviation of the

mean, 95.5% of all readings lie within two standard deviations of the mean and

99.7% of all readings lie within three standard deviations of the mean.

Figure 14: Four different sensors having

different standard deviations.